User Login

-

Welcome, Guest

- ( My Account | View Cart | Login )

Featured Products

Gatsby Steak Knife with SG2 Stainless Damascus San Mai and Cocobolo Liberty Wood (Set of 4)

Edge Guard, 8 in. Chef's Knife (EGS-08C)

Messermeister Edge Guards are a perfect way to protect the edge of your knife. They are especially convenient for in-drawer storage and are perfect for storing and transporting knives in knife rolls and bags.

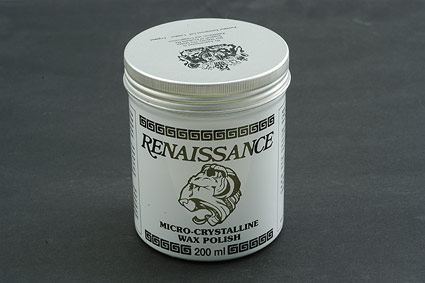

$5.60 DetailsRenaissance Wax (200ml)

Renaissance Wax is the #1 choice of major museums and art galleries for the preservation of the precious pieces.

Renaissance Wax is a revolutionary formula that is a semi-synthetic micro-crystalline fossil-origin wax entirely free of, damaging acids. It remains chemically neutral and is therefore completely safe, even on vulnerable surfaces.

Guard your precious pieces against the damaging effects of humidity, heat, dust, environmental destruction, aging, and ordinary wear. Renaissance Wax provides a barrier against fingerprints and the devastation of water, wine, alcohol and other spills. With its high moisture resistance, it forms a durable, lustrous protective coating. Prevents tarnish, corrosion and "bloom". Remains completely waterproof.

Flitz Metal Polish (150g)

Flitz is an excellent metal polish for carbon steel knives as well as fiberglass. This anti-tarnish formula lasts up to 6 months. It is non-abrasive, non-toxic, non-flammable, acid-free, won't dry out, and leaves behind no residue. Not designed for Damascus steel.

$22.95 DetailsRust Eraser (Sabitoru), Fine (320 grit)

This Rust Eraser nicely cleans and buffs away scratches & light surface rust on metal surfaces and more. 320 grit abrasive is suspended in a slightly "springy" rubber matrix, making it perfect for cleaning up slight imperfections on both curved and flat surfaces. The 320 grit Rust Eraser is very quick to remove rust and scratches and provides a clean looking satin finish. To clean up a surface faster, either start at the 46 grit Rust Eraser or the 120 grit Rust Eraser.. Measures approx. 2 3/4 inches x 1 1/2 inches x 1/3 inch.

Made in Japan.

Camellia Oil, 60ml (2 oz)

For centuries, camellia oil has been used to protect the finest Samurai swords. A small amount applied to your carbon steel knives will keep them free of corrosion and rust. Camellia oil is non-toxic and non-allergenic.

This spray bottle is a great size for professional chefs who want a bottle to carry in the knife bag.

Kai Fish Scaler (DH3016ENG)

Serrated teeth effortless remove fish scales while ensuring less mess than traditional fish scaling with a knife. Fish scales are removed by teeth, while leaving flesh intact -- with less effort and less mess. A rubber guard keeps fish scales from scattering. Made from stainless steel by Kai (Shun) for strength and to prevent corrosion. Dishwasher safe.

$14.95 DetailsChef Steps Ceramic Rod and Cleaner

This set has everything you need to properly take care of your knives.

Ceramic rods provide the best touch up possible between sharpening. By removing very little material, the blade is honed to a razor edge. Fine ceramic rods will hone a knife to the most optimal edge. However, if a considerable time has passed since honing or sharpening, a coarse rod is often required. Generally, a ceramic rod should be approximately the length of the longest knife that you will be honing. This set comes with a 12 inch fine ceramic rod.

Over time, ceramic rods build up metal particles that clog the abrasive surface. The Superaser cleans the surface of all ceramic rods so that they will continue to hone just like they did when they were new.

MAC Kitchen Shears (KS-85) - 8-1/2 inch

I was really excited when the folks over at ChefSteps (www.ChefSteps.com) told me about their favorite kitchen shears. Their recommendations are always pretty spot on. (If you don't know about ChefSteps, go over and check them out!)

MAC's forged kitchen shears really get the job done. They will make quick work out of hard shellfish shells, poultry bones, fish bones, and miscellaneous packaging. One blade is micro-serrated for holding onto slippery surfaces while the other has a razor-polished edge that slices cleanly through tough shells and bones. The drop-forged stainless steel blades are some of the strongest we could find. They are held together by an adjustable nut with a quick-release joint so that you can maintain tight blade-to-blade contact and yet be easily taken apart for cleaning (very important in a kitchen shear!). Strong enough to cut through a penny, these shears were designed for heavy-duty kitchen tasks. Slightly right-handed handle but we know some lefties who use them too. These sharp and smooth functioning shears feature a blue textured/rubber grip.

Made in Japan.

Kai Fish Tweezers

Fish Bone Tweezers help effortlessly remove bones from fish.

- Used for removing bones from freshly filleted fish.

- Ideal for handling small, steaming hot objects that need to be delicately placed on the plate.

- Made in Japan from high quality stainless steel.

- Dishwasher safe.

These Fish Bone Tweezers are made by Kai, the maker of Shun Knives. The angled tweezer makes it very efficient. The ergonomic handle allows either a home user or a professional chef to effortlessly work for extended periods. This Japanese-made tool looks as great as it feels!.

Made in Japan.

Quartered Sycamore Magnetic Knife Strip (18")

This magnetic knife strip can be used for just about anything you can imagine. As long as it's magnet friendly, you're good to go. You'll wonder how you got along without it!

Unlike typical magnetic holders that rely on steel rails, this rack won't ding or nick your high quality blade steel. Your knives will stay sharp longer because wood is edge-friendly. Also, unlike traditional countertop knife blocks, bacteria cannot get trapped in deep slots.

Your knives and tools will be safely secured. With the holding power of rare earth magnets, this strip is capable of holding heavier items such as large hand tools. Holding-power is dependent on shape, friction and size of item. For large items, such as heavier hand planes with a relatively small contact area, we recommend two horizontal racks spaced several inches apart.

To store knives horizontally, two racks can be set vertically spaced several inches apart. The construction methods used to make these strips are such that the entire block seems to be a single piece of wood. Only premium solid hardwoods are used. These magnetic knife holders are backed by a lifetime guaranty.

Unlike typical metal rail magnet bars, these are attractive, designed to accentuate and blend with their environment. Natural sycamore wood figure and tone will vary on each knife strip.

Handmade in the USA.

Gatsby Steak Knife with SG2 Stainless Damascus San Mai and Cocobolo Liberty Wood (Set of 4)

Bradford Knives are handmade in Renton, Washington. His background working in an aerospace machine shop is clearly evident in these high performance, elegant steak knives.

We're very excited about these steak knives. In fact, they are literally some of the best steak knives we've ever seen!.

Super Gold II (SG2) powdered metallurgical (PM) steel is combined with the beauty of damascus cladding. A high performing Takefu SG2 PM stainless steel core is surrounded by thin layers of stainless damascus steel. The resulting cutting edge is tempered to Rc 62 - 63 (very hard!) for exceptional edge holding, but is easy to sharpen due to the small grain structure. The incredibly small crystalline size of this PM steel results in superior edge holding when compared to nearly any other stainless steel used in the knife industry.

The blades are full flat ground for high performance, effortless slicing. They were heat treated by Peters' Heat Treating, for a superior, long lasting edge (Hrc 62-63).

Cocobolo toned Liberty Wood handle scales are set on the full tang using Corby fasteners. Liberty Wood is a natural, engineered wood laminate using sustainably-sourced birch veneer and resin. The water-based resin is infused deep into the wood fibers which acts as a plasticizer and gives the final material its characteristics. Its durability greatly exceeds that of normal hard woods and it is able to obtain a high polish. The handles are nicely contoured with a palm swell.

This four knife set is accompanied by a leather storage pouch, also made in the USA.

Exceptional fit and finish!